Ua Umaview

The Artillery Sidewinder X3 Pro is a high-performance 3D printer designed for both beginners and experienced users. It features a robust build, high-speed printing capabilities, and advanced functionalities to ensure precise and efficient model creation.

Figure 1: Artillery Sidewinder X3 Pro 3D Printer, showcasing its compact and sturdy design.

- Ultra-Quiet High-Speed Printing: Capable of printing at speeds up to 300 mm/s while maintaining high precision.

- 49-Point Auto Bed Leveling: Ensures quick and accurate leveling of the build platform, simplifying the setup process.

- Direct Drive Extruder: Features a newly developed metal direct drive extruder with a dual gear set for higher drive ratio and stronger extrusion force, leading to more accurate extrusion.

- Dual Z-axes & Dual Motors: Enhances stability and printing accuracy by reducing lines and ridges on prints.

- Resume Printing Function: Detects filament runout, breakage, or power loss, allowing printing to resume after recovery, preventing material waste.

Seti ma Fonotaga

The Artillery Sidewinder X3 Pro comes 95% pre-installed, making the initial setup straightforward. Installation to first print typically requires only 4 steps and approximately 10 minutes, even for beginners.

Figure 2: Illustrated assembly steps for the Sidewinder X3 Pro, highlighting the minimal effort required for initial setup.

Laasaga Muamua:

- Tatalaina: Aveese ma le fa'aeteete vaega uma mai le afifiina. Ia mautinoa o lo'o iai vaega uma o lo'o lisiina i le lisi o afifiina.

- Base and Gantry Assembly: Attach the gantry to the printer base using the provided screws.

- So'oga uaea: Connect all necessary cables, ensuring they are securely fastened. Pay attention to the hotend and extruder connections.

- utaina o filament: Load your chosen filament into the direct drive extruder.

- Malosiaga: Fa'afeso'ota'i le uaea eletise ma ki le lomitusi.

Fa'atonuga o Galuega

Fa'aoga fa'aoga:

The Sidewinder X3 Pro features a 4.3-inch full-color touchscreen with large icons, providing a simple and feature-rich interface that helps prevent misoperation.

Figure 3: The 4.3-inch full-color touchscreen interface of the Sidewinder X3 Pro, designed for intuitive navigation.

Auto Bed Leveling:

The newly upgraded 49-point auto bed leveling system ensures the build platform is quickly and accurately leveled, which is crucial for successful first layers and overall print quality.

Figure 4: Visual representation of the 49-point smart auto-leveling process, which automatically measures and adjusts the print bed.

Lomiga Saosaoa:

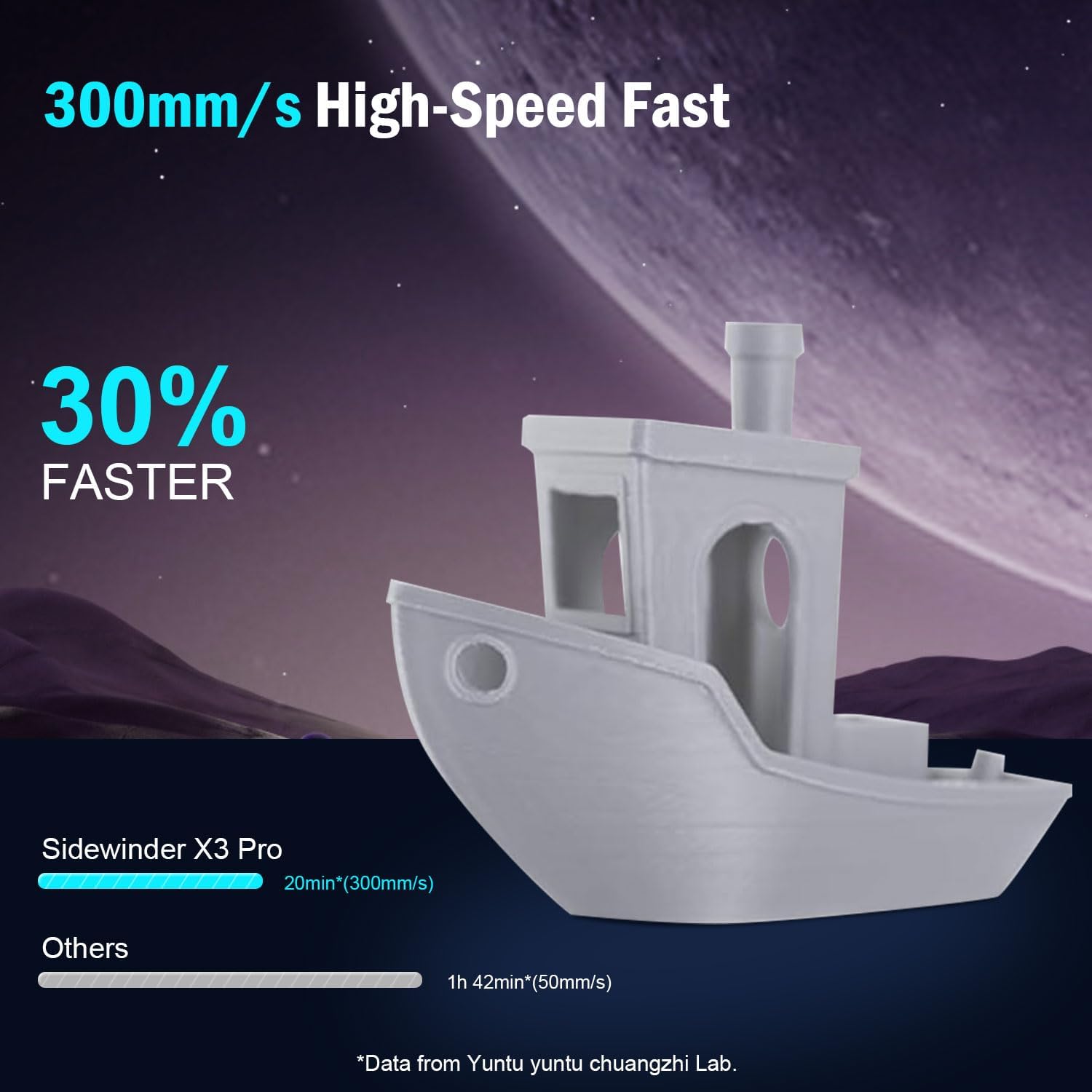

The Sidewinder X3 Pro is engineered for high-speed printing, reaching up to 300 mm/s, allowing for faster completion of prints without compromising precision.

Figure 5: Comparison illustrating the speed advantage of the Sidewinder X3 Pro at 300mm/s compared to slower printers.

Extrusion System:

Equipped with a dual-gear direct extruder, the printer provides powerful and smoother filament feeding, which is essential for consistent and high-quality prints. The all-metal automatic cleaning hotend supports printing temperatures up to 300°C.

Ata 6: Auiliiliga view of the dual-gear direct extruder, designed for powerful and precise filament extrusion.

Figure 7: Illustration of the all-metal automatic cleaning hotend, capable of reaching temperatures up to 300°C.

Print Stability and Accuracy:

The dual Z-axes and dual motors design ensures stable movement of the print head and contributes to higher printing accuracy by minimizing artifacts like lines and ridges on your prints.

Figure 8: Diagram showing the dual Z-axes and dual motors, which provide enhanced stability and precision during printing.

Print Volume and Build Plate:

The printer offers a print size of 9.44" x 9.44" x 10.23" (240mm x 240mm x 260mm), suitable for a wide range of projects. It features a PEI Magnetic Platform with a maximum hotbed temperature of 100°C. Models can be easily removed by slightly bending the platform once cooled.

Figure 9: Illustration of the print volume dimensions and the PEI magnetic build platform, demonstrating easy print removal.

Tausiga

Regular maintenance ensures the longevity and optimal performance of your Artillery Sidewinder X3 Pro 3D printer.

- Hotend Cleaning: The printer features an automatic cleaning hotend. Periodically inspect the nozzle for any residue or clogs.

- Tausiga Papa Faufale: Clean the PEI magnetic build plate after each print to ensure good adhesion for subsequent prints. Use isopropyl alcohol for best results.

- Lubrication: Apply a small amount of lubricant to the Z-axis lead screws and smooth rods periodically to ensure smooth movement.

- Faʻalauiloa Firmware: Siaki le ofisa aloaia o le Artillery web'upega tafaʻilagi mo soʻo se faʻafouga o le firmware o loʻo avanoa e faʻamautinoa ai o loʻo iai i lau masini lomitusi foliga aupito lata mai ma faʻasaʻoga o mea sese.

- Fa'amamaina lautele: Keep the printer free of dust and filament debris. Use compressed air to clean hard-to-reach areas.

Fa'afitauli

This section provides solutions to common issues you might encounter during the operation of your Sidewinder X3 Pro.

| Fa'afitauli | Mafuaaga e ono tupu | Fofo |

|---|---|---|

| Print Not Sticking to Bed | Improper bed leveling, dirty build plate, incorrect bed temperature. | Perform auto bed leveling. Clean the build plate with isopropyl alcohol. Adjust bed temperature according to filament type. |

| Filament Not Extruding | Clogged nozzle, tangled filament, incorrect hotend temperature, extruder issue. | Check hotend temperature. Clear nozzle clog using a needle or cold pull. Ensure filament spool is free and untangled. Inspect extruder for proper function. |

| Printer Stops Mid-Print | Filament runout/breakage, power loss, corrupted G-code. | Utilize the resume printing function. Check filament path. Ensure stable power supply. Reslice and re-upload G-code. |

| Poor Print Quality (Layer Shifts, Stringing) | Loose belts, incorrect print speed, retraction settings, temperature. | Check and tighten belts. Adjust print speed. Calibrate retraction settings in slicer. Optimize hotend temperature. |

| Touchscreen Unresponsive/Incorrect Language | Software glitch, loose connection, corrupted firmware. | Restart the printer. Check display cable connections. Consider re-flashing firmware if issue persists (refer to Artillery support). |

For more complex issues or if the problem persists, please refer to the Warranty and Support section for contact information.

Fa'amatalaga

| Fa'aaliga | Fa'amatalaga |

|---|---|

| Fa'ata'ita'iga | Sidewinder X3 Pro |

| Fa'ailoga | Autau |

| Fua o Mea | 17.6 x 9.76 x 19.7 inisi (447 x 248 x 500 mm) |

| Mea mamafa | 24 pauna (10.89 kilokalama) |

| Mea | Uamea |

| Lanu | Lanu uliuli |

| Max Lolomi Saosaoa | 300 mm/s |

| Faʻavasegaina taʻavale | 49-Point Auto Bed Leveling |

| Ituaiga Extruder | Lua-Gear Direct Drive Extruder |

| Max Hotend Temperature | 300°C (All-Metal Hotend) |

| Ipu fausia | PEI Magnetic Spring Steel |

| Max Hotbed Temperature | 100°C |

| Z-axis Design | Dual Z-axes & Dual Motors |

| Feso'ota'i | SD Card, USB (assumed) |

| Fa'aoga Fa'aoga | 4.3-inisi Mata Pa'i Lanu Atoa |

Ata 10: Fa'asili i lugaview of the Artillery Sidewinder X3 Pro 3D Printer.

Fa'amaonia ma Lagolago

Artillery provides a one-year warranty for the Sidewinder X3 Pro 3D Printer. Additionally, 24-hour after-sales service is available to assist with any inquiries or issues you may encounter.

For technical support, warranty claims, or general inquiries, please contact Artillery customer service through their official channels. Refer to the product packaging or the official Artillery webnofoaga mo fa'amatalaga fa'afeso'ota'i sili ona lata mai.

It is recommended to keep your purchase receipt as proof of purchase for warranty purposes.